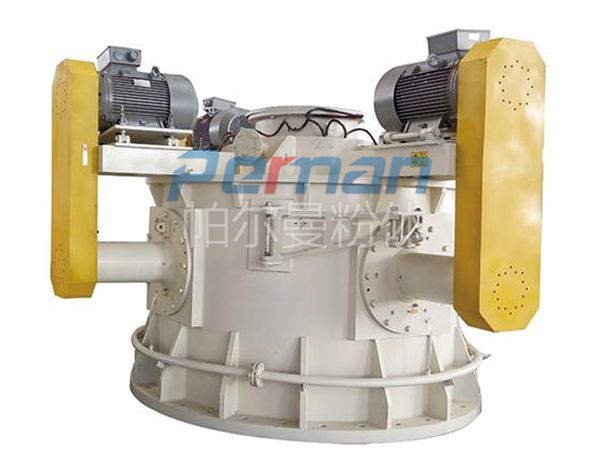

FW horizontal multi rotor classifier

Product Introduction

Ultra fine vertical grinding and graded ultra-fine processing technology and equipment (imported from Taiwan's grinding roller technology)

The integration of ultra-fine vertical mill, ultra-fine classifier, and automatic control technology is a new trend in the processing of ultra-fine non-mineral powder in the world today. Due to its significant energy-saving characteristics, it is increasingly widely used in various regions around the world. Taiwan is at an advanced level in producing non-metallic minerals, especially ultra-fine white minerals such as ultra-fine heavy calcium, using ultra-fine vertical mills.

At present, we are drawing on Taiwan's ultra-fine vertical grinding technology to design the process and complete the equipment for the ultra-fine vertical grinding system. The product quality and energy consumption technical indicators of the new vertical mill system have reached the advanced level in Taiwan, and the mechanical stability performance has exceeded the level of Taiwan's vertical mills.

Performance characteristics:

● Ultra fine grinding and grading significantly reduce electricity consumption (compared to ball milling, electricity consumption per ton of product is reduced by 20-40%);

●Multi round classification, high cutting accuracy, moderate fine powder content of the product, uniform particle size distribution, and good adaptability;

●It can produce 1500 mesh products at once, and the product variety can be adjusted from 325 to 1500 mesh;

●The classification technology adopts Germany's new NG technology, with foldable trapezoidal blade classification impellers, which reduce back pressure by more than 30% compared to conventional impellers and correspondingly reduce fan energy consumption by 20-30%;

●The main machine and fan of the vertical mill are all controlled by frequency conversion, with a highly automated system design and a computer operation interface.

Application field:

Widely used in large-scale ultrafine dry powder processing of non-metallic mineral powders, such as calcite, barite, and talc.